COMFORT PACKAGE | |

| Electric BBQ built into wetbar with Corian lid in cockpit | |

| Cotton pascale, quilted double bed fitted mattress protectors | |

| Canopy shade for foredeck and 2x large bean bacg (or foldable deck seats) | |

| Four button remote for C-Zone system | |

ELECTRONICS UPGRADE | |

| Additional 2nd Garmin GMI 20 repeater screen at inside nav station | |

| Garmin AIS 800 transceiver (receiver is standard) | |

BATTERY UPGRADE

no charge for these, as it’s already included in the standard specifications! | |

| Upgrade to 20kWh Li-ion batteries | |

| High output Mastervolt alternators with extrenal smart controllers on both engines (110Ah on 24V) | |

ENTERTAINMENT PACKAGE | |

| 1x TV in master cabin | |

| 2x Bose speakers to be fitted on spreaders | |

| 4 x Underwater LED lights | |

| Apple TV | |

COMMUNICATIONS PACKAGE | |

| Cellular Modem / WiFi Router Antenna System | |

| Iridium Go with external aerial on spreader | |

| Starlink High Performance Dish with TP Link High Perfromnace router | |

FLEXITEEK DECKING | |

| Flexiteek on cockpit floor, steps to helm station and helm station floor and transom and transom steps | |

SAILS | |

| Code 65 – 130m² on bowsprit and Facnor electric furler. Sheets led back to electric winches at helm station | |

| Furling Gennaker with top down swivel. Sheet led back to electric winches at helm station | |

| Upgraded running rigging | |

PROPELLER UPGRADE | |

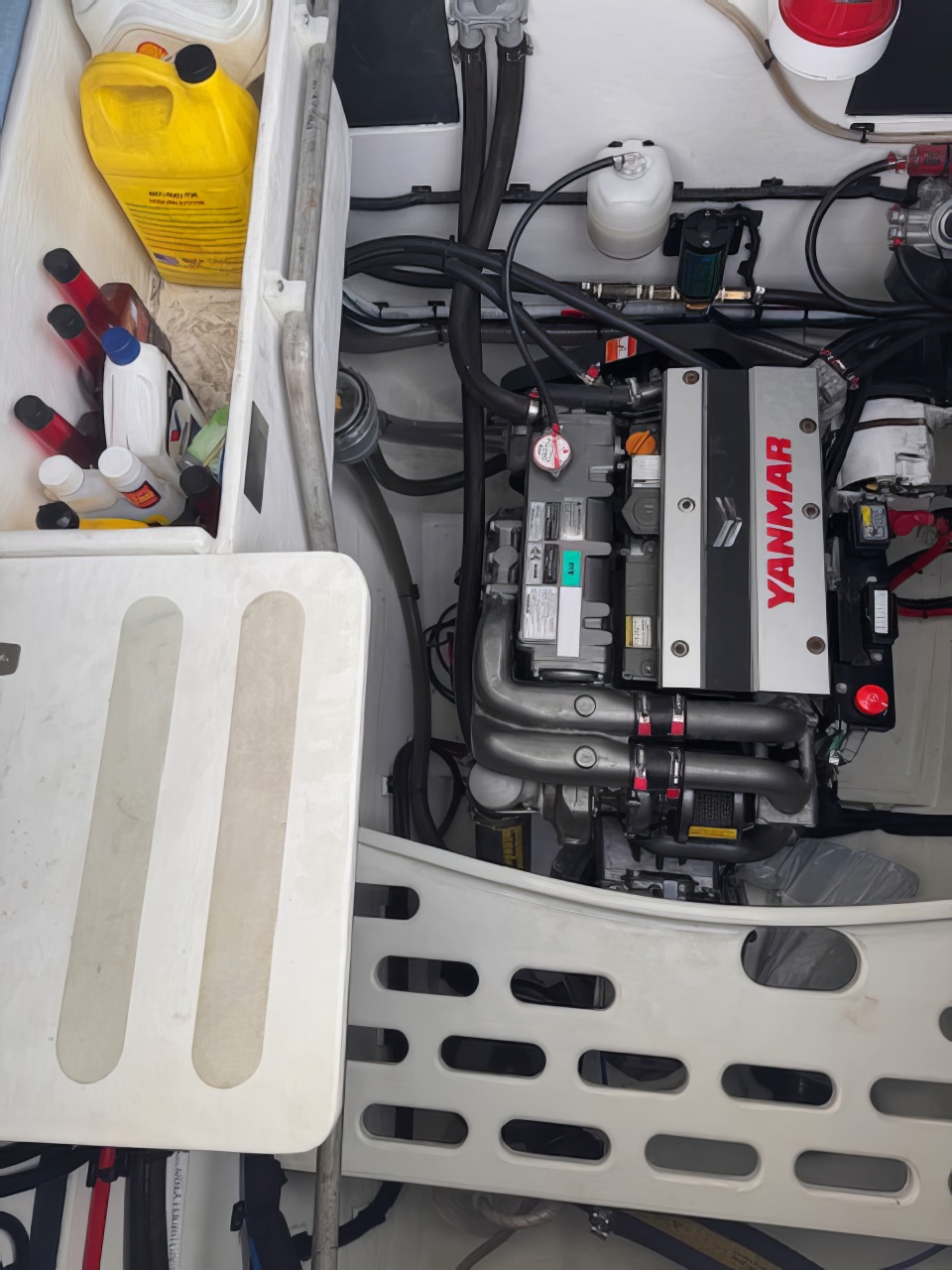

| Gori 3 blade folding propellers with rope cutters | |

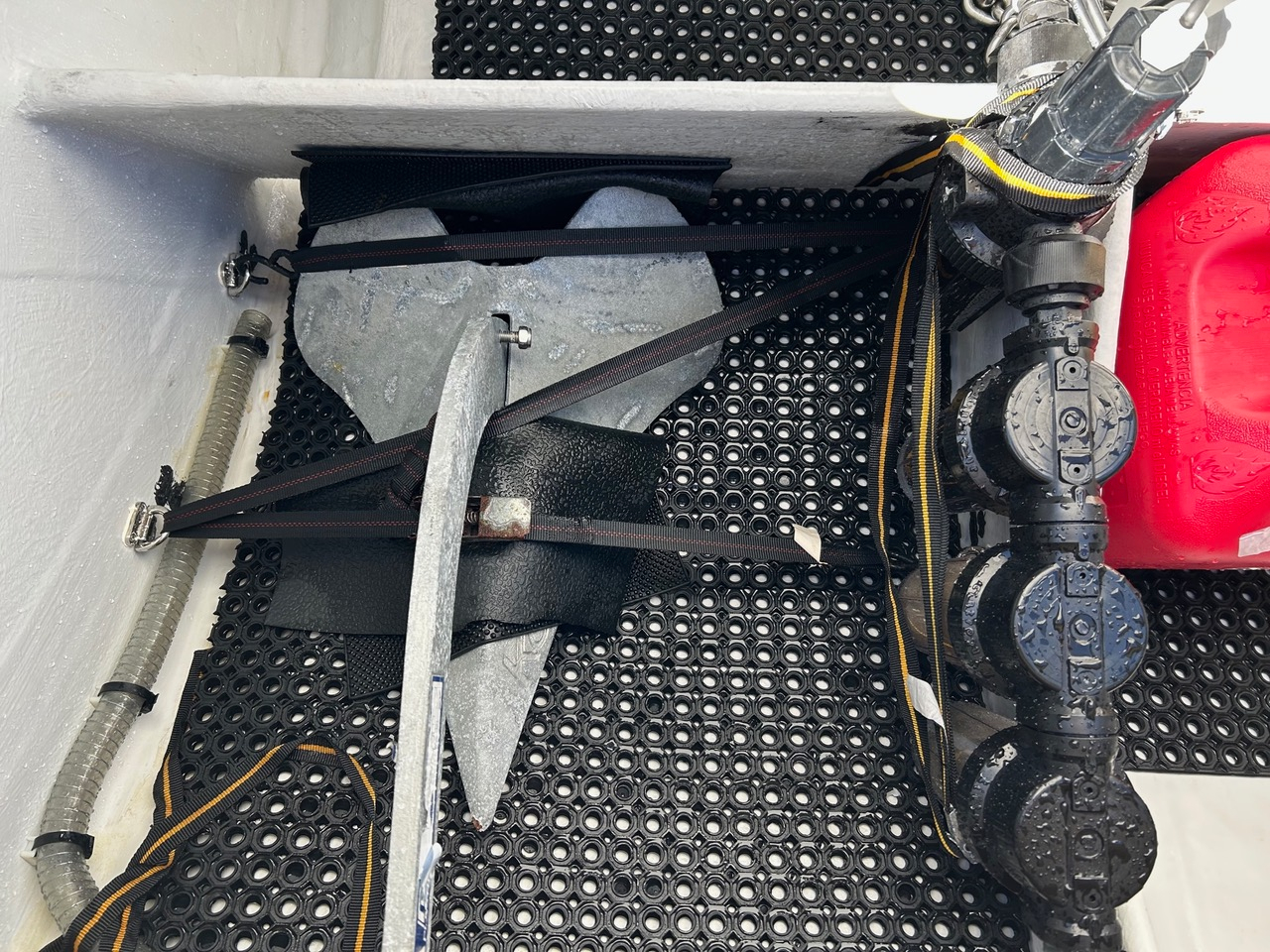

SCUBA PACKAGE | |

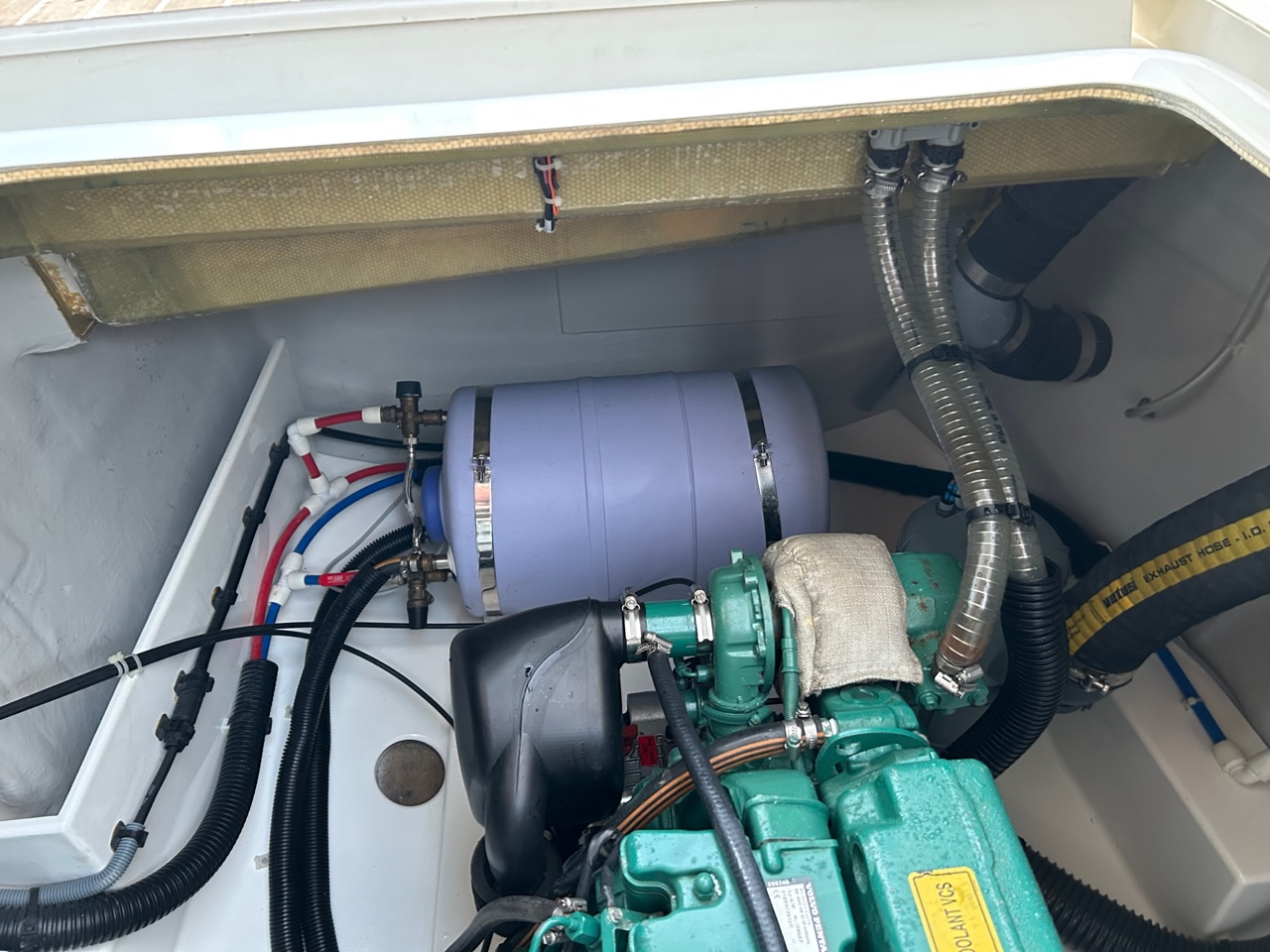

| Coltri-6/EM INOX electric dive compressor – Condensate drain with automatic timer | |

| 4 x 12L Dumpie Dive Tanks plus holder and filling hose | |

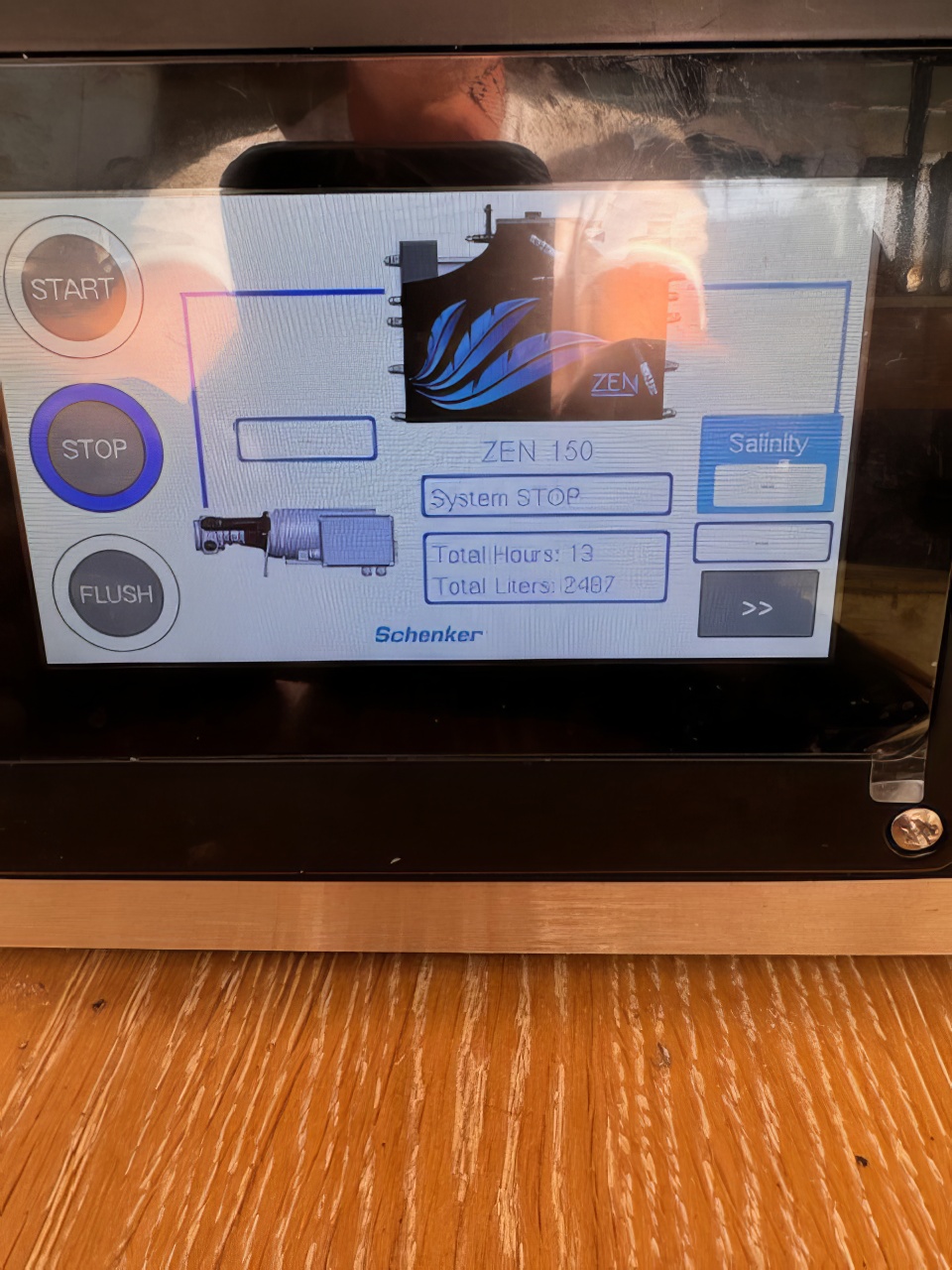

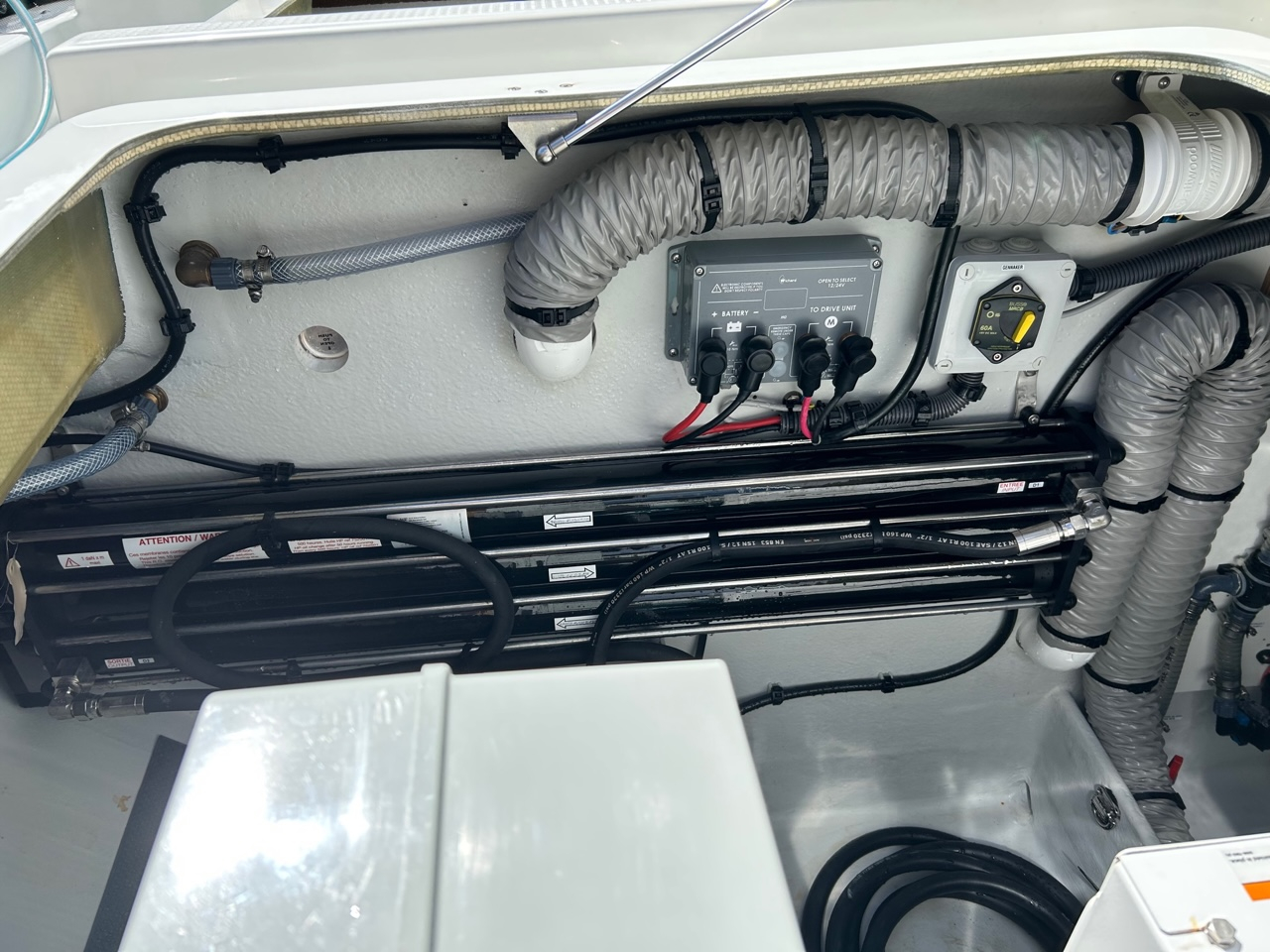

WATERMAKER UPGRADE | |

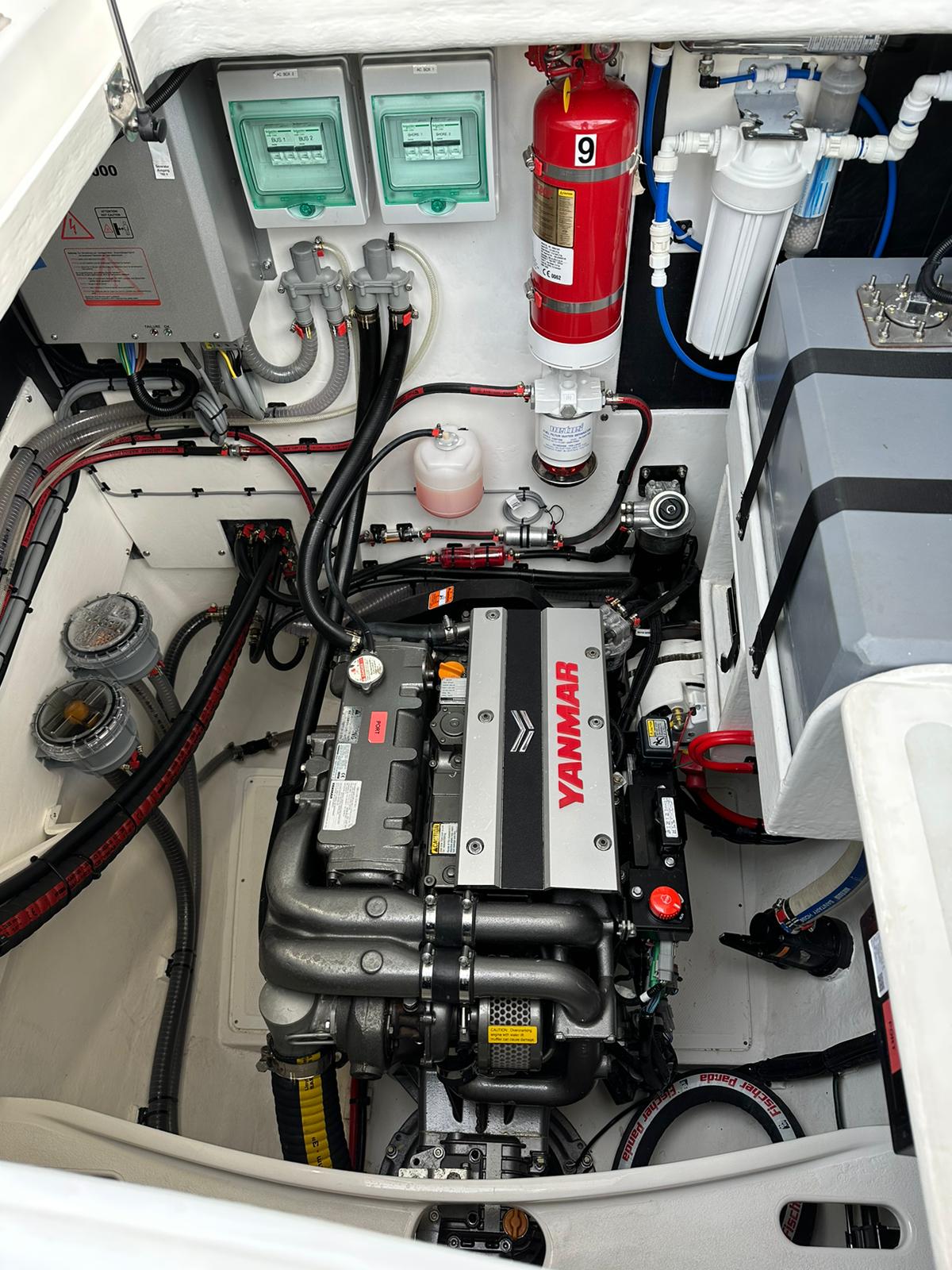

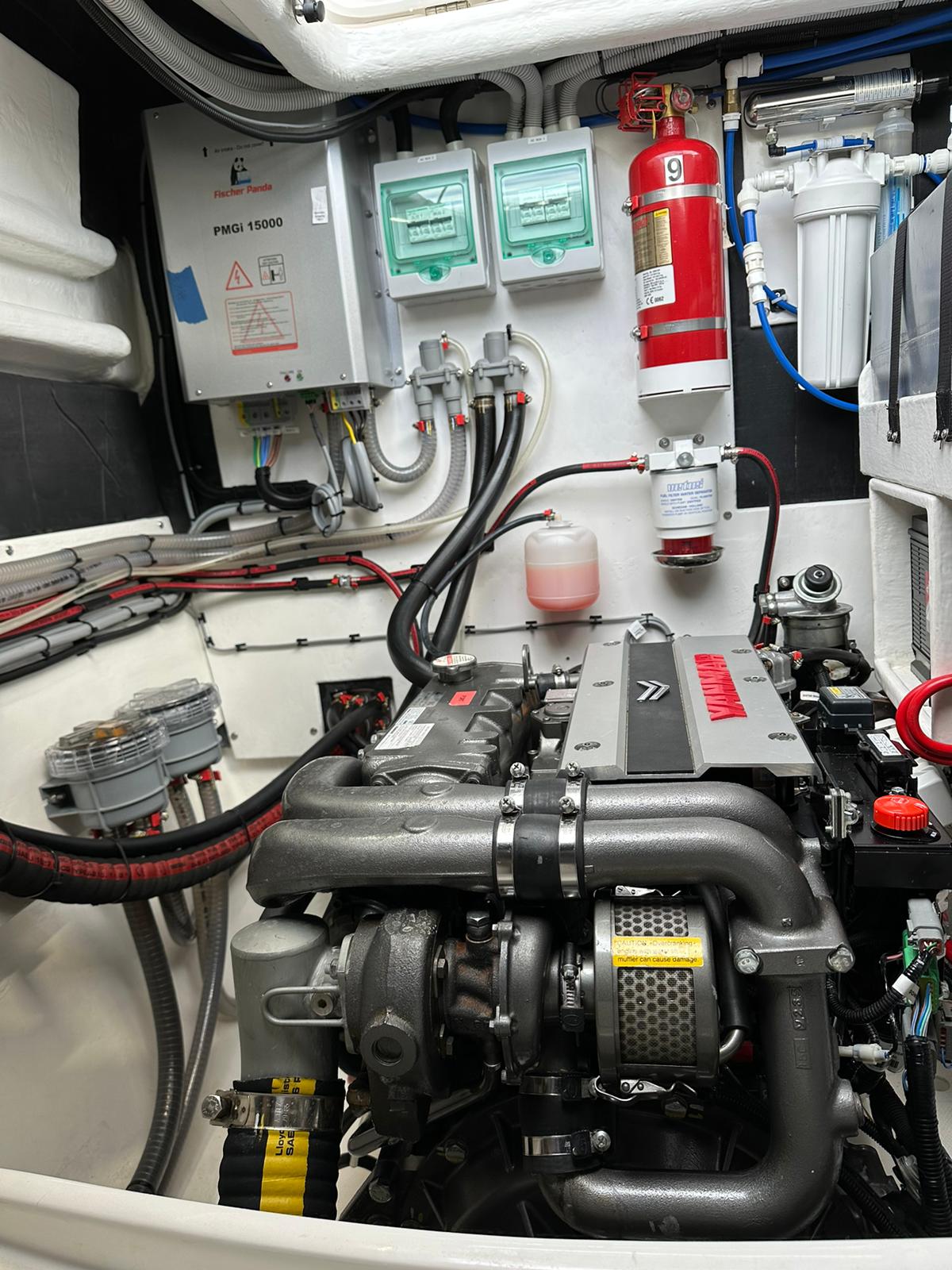

| Water maker – Newport NP-MK IIZ-1000 fully automatic with backwash fresh water flush – 150Ltr/hr (in lieu of Newport 400) | |

SAFETY EQUIPMENT | |

| 2 EPIRBS | |

| Lifesling | |

| Fully equipped ditch bag | |

| High output emergency bilge pump | |

| MOB inflatable IOR Dan Bouy | |

| Strobe lights | |

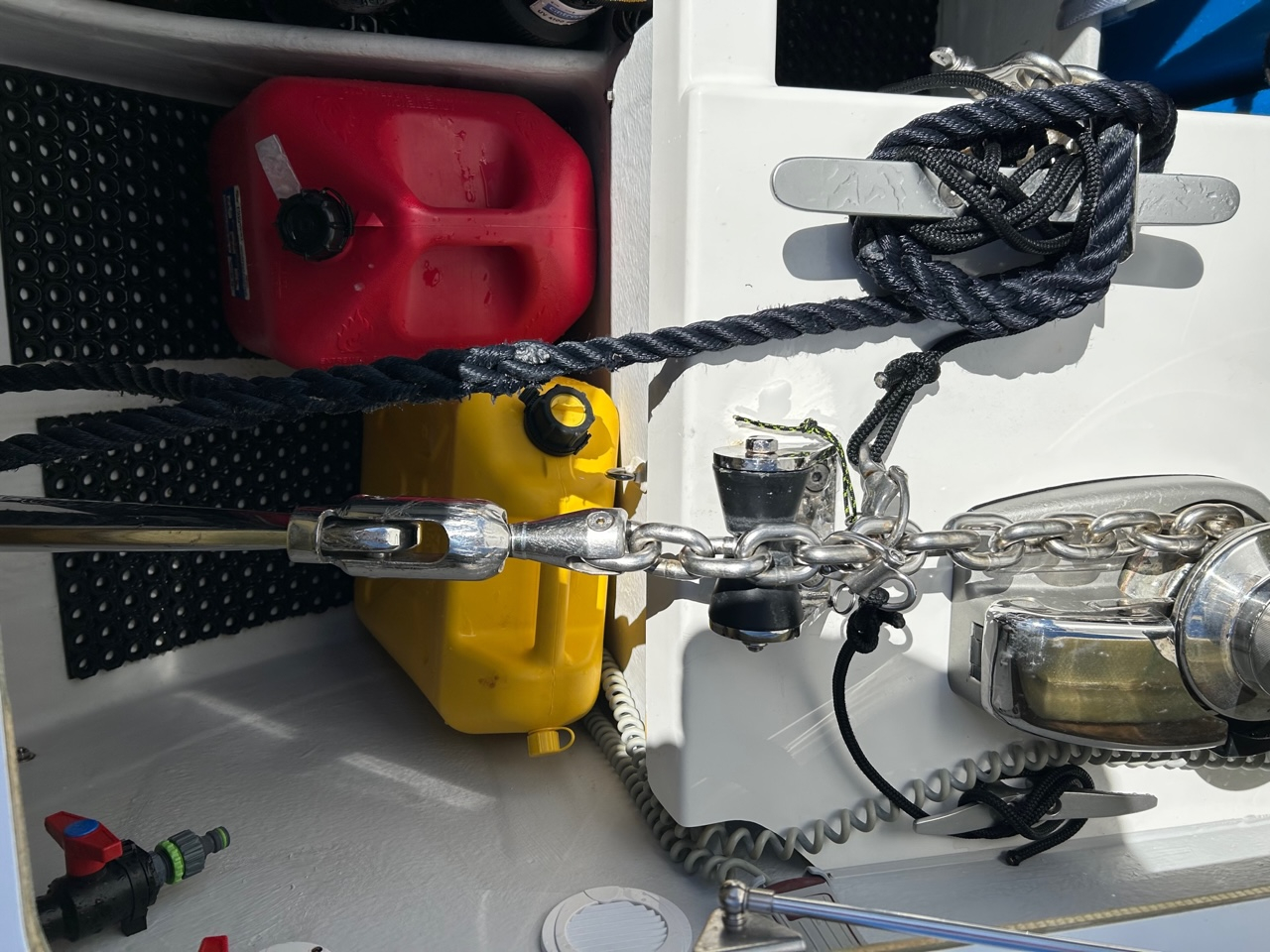

ANCHOR UPGRADE | |

| Stainless steel ULTRA anchor with flip swivel (in lieu of DELTA) | |

SPARES AND TOOLS | |

| Tool cabinet instead of standard drawers or additional freezer | |

| Professional tool kit in foam inserts in tool cabinet | |

| Comprehensive spares kit | |

DINGHY & OUTBOARD ENGINE | |

| AB 12′ aluminum hull tender with Yamaha 25HP EFI outboard engine (fitted with starter battery, fuel filter, electric bilge pump, custom lifting bridles for dinghy davits) | |

WORLDWIDE DELIVERY | |

| Delivery to USA/Caribbean/Mediterranean aboard cargo ship | |

CUSTOMIZATIONS | |

COLORS | |

| Furniture – Oak Lime Textured Mat | |

| Floor – Sash Oak (grey) | |

| Upholstery – Sterling | |

| Countertops – Light Grey | |

| Accent Panels – Platinum | |

| Headliner – Off-White | |

| Baseboards, trims and bathroom doors – Brown greyish formica (don’t know the name) | |

| Outside Upholstery – Titanium | |

| Flexiteek – Weathered with white caulking | |

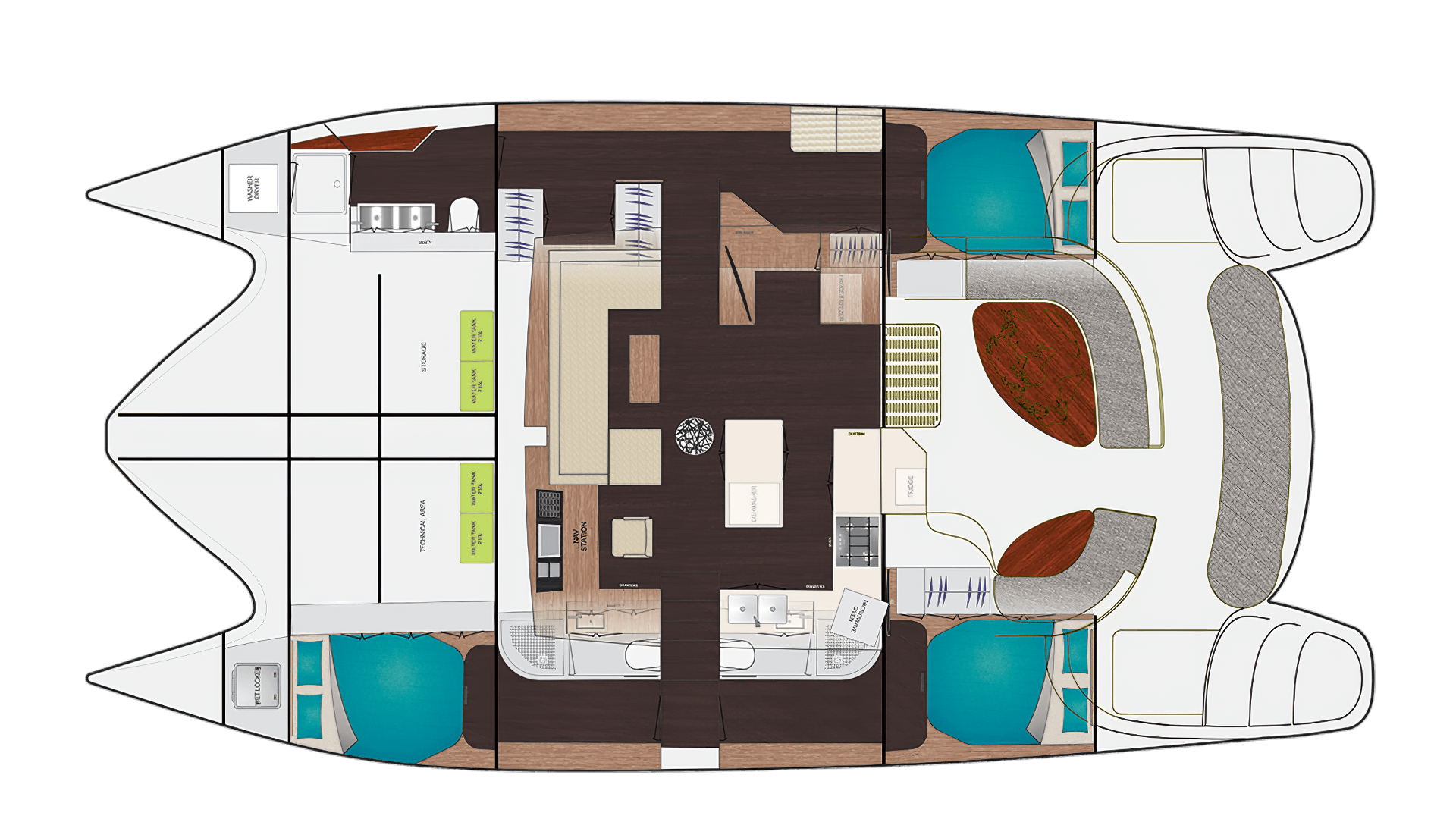

MASTER CABIN | |

| Leather pouch (9in wide x 7in tall; bottom of pouch positioned 22in from ceiling of cabin, it lines up with line dividing two accent panels in the head board of the beds) attached to headliner on outboard side of master cabin – made to store phone, iPad, earphones, small charger… | |

| Bookshelf above vanity table in master cabin | |

MASTER BATHROOM | |

| Intstall double tower rack high up so cabinet can open on same wall as toilet paper holder (consider lowering toilet paper holder slightly so there is more space for towels) | |

| Install fidle made of alum or something else to create storage on top white structural beam/shelf on outboard side above window. This could then be used for keeping an air freshener and other bathroom decoration or supplies | |

| Bench seat outside of shower in Light Grey (same material and color as countertops) | |

PORT CABINS | |

| Port Bathrooms – Solid light frosting (similar to X5) all around for complete privacy when someone is using the head/toilet. Use frosting with a design around the shower area for aesthetic purposes, not for privacy, i.e. the purpose is to blend in with the frosting around the toilet area vs. create privacy in the shower. | |

| Port Bathrooms (for both bathrooms) – Install double towel rack (not a second rack under existing one, but a rack with 2 rods, 1 in front of the other, so both towels can hang without being on top of each other). | |

| Port aft cabin only – Leather pouch (9in wide x 7in tall; bottom of pouch 22in from ceiling of cabin, it lines up with line dividing two accent panels in the head board of the beds) attached to headliner on outboard side of master cabin – made to store phone, iPad, earphones, small charger… | |

SALOON | |

| Main table that can be used as coffee table, daybed and dining table. | |

ADDITIONAL ITEMS | |

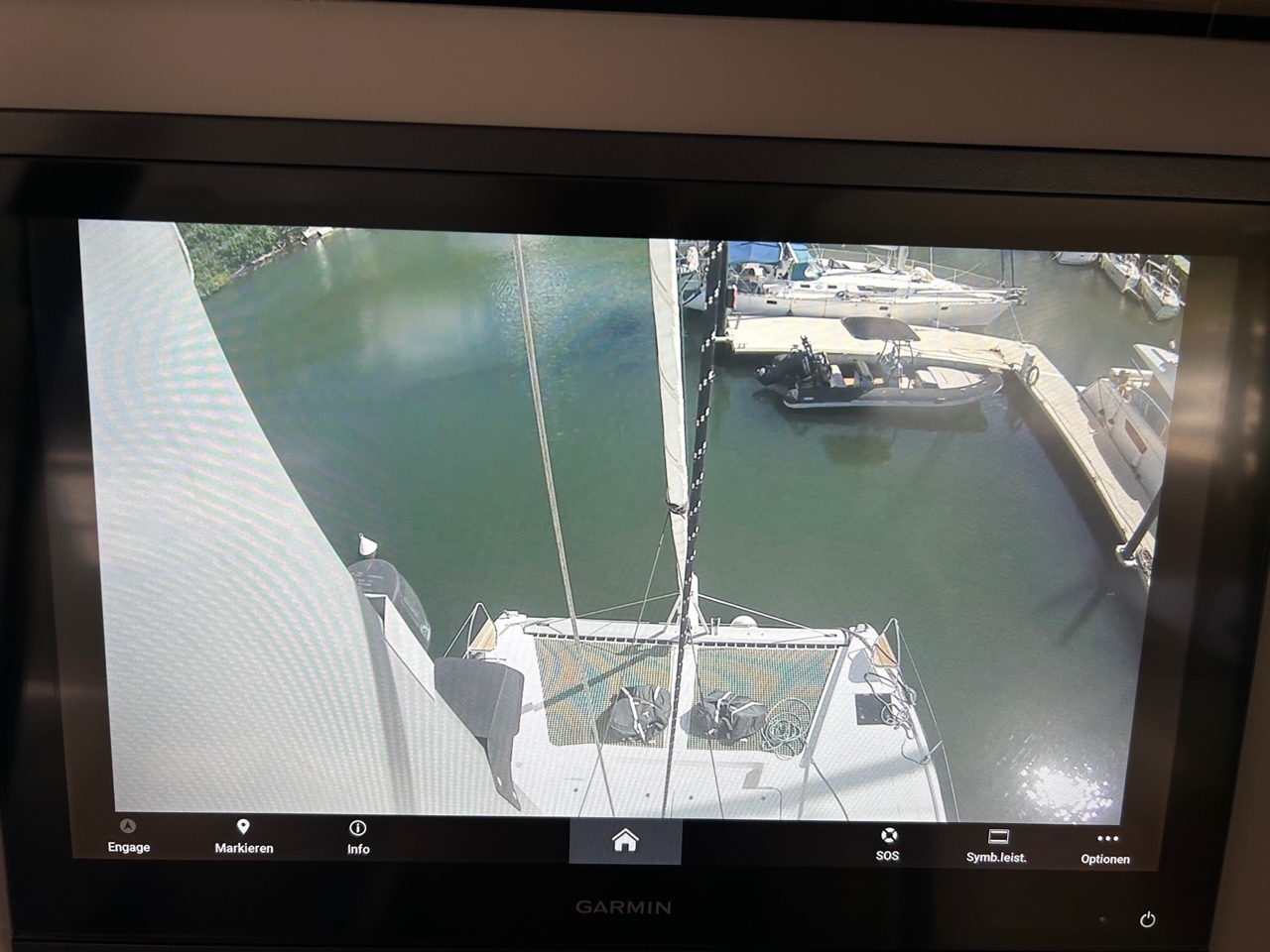

| Camera on top of the mast | |

| Dometic Electric Cooler CFX3 75L (not 95L – too big). Includes cover and cushion on top | |

| Change middle stainless steel wire to Dynema life lines all around | |

| Install multiple attachment points in the ceiling of cockpit (primarily targa area) to dry wetsuits, towels, kites, impact vests… We will have lots of wet and heavy gear that will need to be hung often. Points to be installed in a way so that a line can be tied and wetsuits can be drying without water dripping on top of cushions but in the passage area. | |

| Fishing rod holders | |

| Yachtrouter system (wifi/cellular booster) | |

| Extra backrest at helm | |

| Parasailor pre-install (only the fixed hardware) | |

| Ethernet cables from Yacht router to both TVs | |

| Dinghy and full setup with 1st aid kit and mini fire extinguisher | |

| Fully equipped galley with breadmaker, toaster, blender, instant pot, vacuum sealer, soda stream, pots and pans, plates, bowls, cups, cutlery, etc. | |

| Fishing gear | |